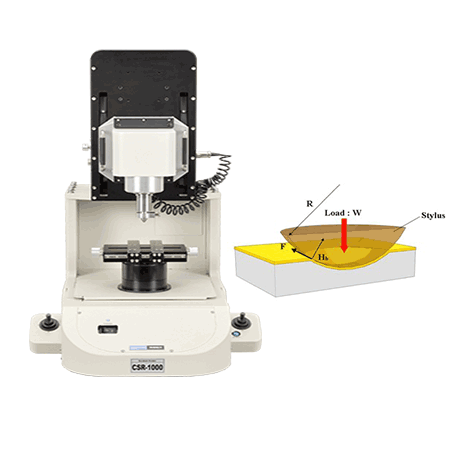

The Rhesca CSR1000 Tester is designed to excel in quantitative measurement of adhesion strength of hard film (Ti, TiN, SiC, DLC) by PVD and CVD on the metal surface. The testing instrument is perfect for the evaluation of coating film on machined parts, decorative coatings, cutting tools and mold tooling. The instrument comes with a standard load cell of 30Kg but optional load cells are available upon request. Other optional accessories can be a Rockwell sensor, acoustic emission (AE) sensor and various diamond tip stylus sizes.

Key Benefits

- Detects the peeling point (breaking point) of the film from the change in frictional force

- The applied load and frictional force are displayed in a graph in real time.

- Simultaneously collects Stress (friction force) and load value (applied load) using a single load cell

- Linear load control through an active feedback mechanism.

- Easily position test specimen measurement with build in joysticks.

- Measures fracture sound by AE sensor to add detection of the peeling point of the film (optional).

Specifications

|

Load range |

1 N- 294N (Z & Y axis), 30Kg load cell as standard |

|

Load resolution |

0.1% FS |

|

Scratch Speed |

0.01 to 1.00 mm/sec |

|

Traveling range |

Z axis 70 mm |

|

Stage travel |

XY (100 mm) |

|

Power supply |

AC100 to 240V 50/60Hz 50W |

|

Main unit size |

485(W) x 615(D) x 790(H) mm |